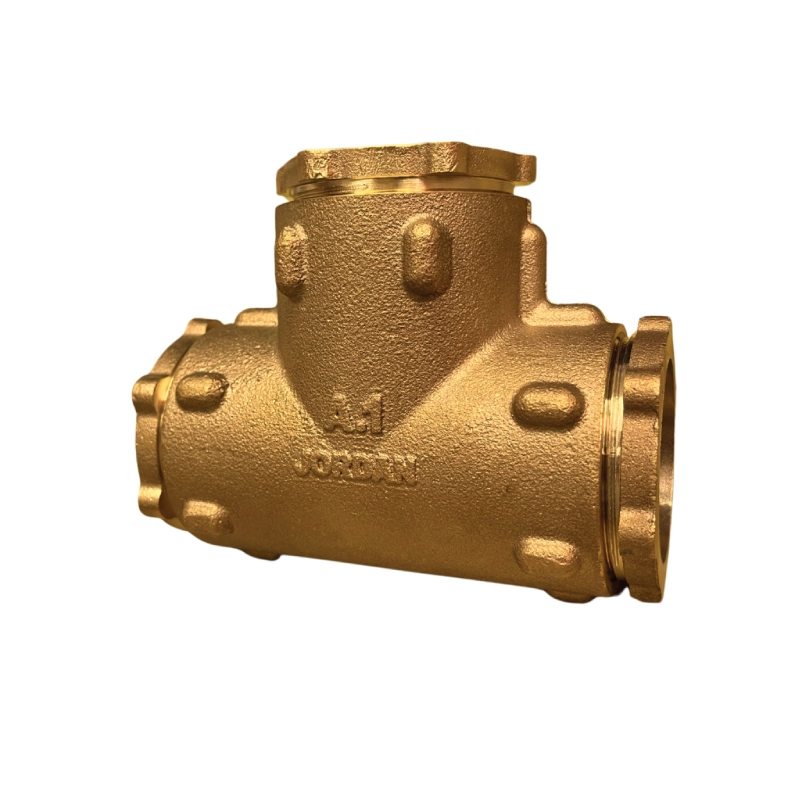

Gunmetal Fittings equal tee – compression type for PE pipes

Made from corrosion immune materials, A.1 Jordan® Gunmetal Fittings provides years of trouble free service in even the most arduous of ground conditions.

FITTINGS COVER A VARIETY OF PIPE MATERIAL AND SIZE

Fittings for metric and imperial PE pipe, 20mm (1/2″”) to 63mm (2″”)

Fittings for steel threaded pipe, 1/2″” to 2″” BSP.

Fittings for copper pipe, 15mm to 54mm

When ordering fittings for PE pipes, it is necessary to state the British Standard number for the pipe together with the nominal size of the pipe stated in the said standard, and the class of the pipe, e.g. BS 1972, 1/2 class C.

A.1 JORDAN® Pushfit Fittings for PE pipe are suitable for polyetylene pipes that comply with the requirements of BS 1972, BS 1973, BS 3284, BS 3796 and ISO 4427.

BENEFITS

Ease and quickness of installation: the pipe is easily inserted into the grip ring and pass-through the rubber “”O”” ring that provides the seal.

SEALING

Any pullout tensile action either by hand or as a result of the rise in water pressure, is resisted by the tightening of the “”O”” ring and the grip ring as both would be pushed down the taper of the pipe fitting, thus increasing the sealing pressure against the pipe and body of the fitting.

STRENGTH

The joint and the fitting are tested to 48 bars, and the pipe will fail before either the connection or the fitting does.

STANDARDS

Pushfit joint meets the requirements of WIS No. 4-32-11, ISO 3458, ISO 3459, ISO 3501 and ISO 3503.

SUITABILITY

The fittings are suitable for the maximum working service pressures and temperatures specified for the pipes in BS 1972, BS 1973, BS 3284 or BS 3796 as applicable, namely 18 bar at 85°C.

MATERIALS

The fittings are in Gunmetal to BS 1400 LG2 cast.

The “”O”” ring is in EPDM rubber that is WRAS-certified for use in contact with potable water up to 85°C.

The grip ring is in Hostaform C13031® acetal copolymer material or equivalent.

COMPRESSION FITTINGS FOR PE PIPE

Including Poly Adapters, can be supplied in one of the following two versions, the only difference between the two versions being the size of the copper insert:

Fittings for PE pipes to BS 1972 class “”C””: these will also fit PE pipes to BS 1973 class “”C””.

Fittings for PE pipes to BS 3284 class “”C””: these will also fit PE pipes to BS 3796 class “”C”” and four PE Pipes to ISO 4427.

BENEFITS

Ease of installation: no need for special tools for making the joint.

SEALING

Any pullout tensile action either by hand or as a result of the rise in water pressure, is resisted by compression of the rubber ring, thus retaining the pipe even more securely while maintaining a watertight seal.

STRENGTH

The joint and the fitting are tested to 48 bars, and the pipe will fail before either the connection or the fitting does.

STANDARDS

Compression Fittings for PE pipe conform with the requirements of BS 864: Part 3 Type A. Compression joint for PE pipe meets the requirements of BS 5114, ISO 3458, ISO 3459, ISO 3501 and ISO 3503.

SUITABILITY

The fittings are suitable for the maximum working service pressures and temperatures specified for the pipes in BS 1972, BS 1973, BS 3284 or BS 3796 as applicable. Moreover, they are capable of working at a continuous pressure of 18 bars without leaking and a temperature of up to 85°C.

INSTALLATION

Pushfit Connection

The end of the pipe should first be beveled and the pipe inserted fully into the fitting with a slight twist, while ensuring that it passes two points of resistance

Compression Connection

Ensure that the end of the pipe has a straight square face

Insert the thrust nut (threads facing outwards), then the friction washer, then the rubber compression ring, into the pipe.

Knock the copper insert into the pipe until its face touches the insert flange. This should be done with care so as not to damage the insert flange.

Push the rubber compression ring and the friction washer against the insert flange and locate this assembly into the compression end of the fitting.

Hand-tighten fully the thrust nut into the compression end of the fitting, then tighten it further about 11/2-to-2 turns using a spanner.

| Size |

½" ,¾" ,1" ,1¼" ,1.1½" ,2" |

|---|

You must be logged in to post a review.

Reviews

There are no reviews yet.