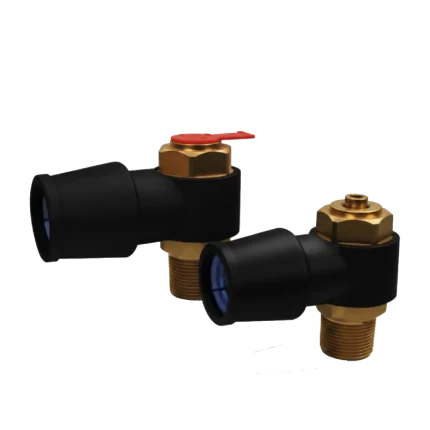

Stopcock with Crutch Head

The Range of Stopcocks consists of many individual types, all of which

give excellent performance characteristics. The range is available with

the following ends or a combination thereof:

• Ends with parallel female (BSP) threads that comply with the

requirements of BS 2779 and BS 21.

• Pushfit-type ends for polyethylene pipes that comply with the

requirements of BS 1972, BS 1973, BS 3284 and BS 3796.

• Compression-type ends for polyethylene pipes that comply with the

requirements of BS 1972, BS 1973, BS 3284 and BS 3796.

The A.1 JORDAN® Stopcocks, depending on the type of pipe for

which they are designed, are suitable for the maximum working

pressures and temperatures specified in the previous sections of this

catalogue as applicable.

Stopcocks conform to the requirements of BS 1010: Part 2 and BS 5433.

They can be supplied in one of the following versions:

• With Crutch Head.

• With the Spindle Shielded so as to prevent unauthorized operation

with a wrench, the spindle being of such size that it can be operated

by a standard key operator, and the shield being of sufficient depth

so that when the valve is fully open, the spindle remains recessed in

the shield to a depth of 5mm. The shield having two holes drilled

opposite each other at its open end to allow insertion of a sealing

wire. The Stopcock can be provided with a detachable key operator.

Gunmetal Stopcocks are available in 20, 25, 32, 40, 50 and 63mm as

well as their imperial equivalents: 1/2″”, 3/4″”, 1″”, 1.1/4″”, 1.1/2″” and 2.

| MATERIALS |

• All metallic components are in Gunmetal to BS 1400 LG2 cast.

• The sealing washer is in EPDM rubber that is WRAS certified for use

in contact with potable water up to 85°C.

• The head seal “”O”” ring is in EPDM rubber that is WRAS-certified for

use in contact with potable water up to 85°C.

• The gland packing material is in high tenacity polyacrylic yarn treated

with PTFE and WRAS-certified for use with potable water up to

85°C. As well as, a washer can be fitted in EPDM rubber that is

WRAS certified for use with potable water up to 85°C.

• Other components in the outlet end socket, depending on the type of

pipe, are in materials as specified in the relevant section in the preceding

pages of this catalogue.

THREADING

• All threads are of Whitworth form and right-handed, and comply with the requirements of BS 1010: Part 2 and BS 5433.

• Inlet and outlet threads of stopcocks with BSP (parallel) female threaded ends comply with the requirements of BS 2779.

BORE

• The area of waterway throughout the valve body is not less than the area of a circle of diameter equal to the bore of the seating.

DIMENSIONS

• Dimensions for valve bodies and components (including wall thickness and thickness of screwed ends) satisfy the dimensional requirements of BS 1010: Part 2 and BS 5433.

TESTING

• Every stopcock is tested against leaking and sweating in the assem- bled condition both in the fully closed position (seat test) and in the fully open position (body test), by applying a hydraulic pressure of not less than 21 bar.

MARKING

• Markings are engraved and/or cast. Each stopcock is legibly marked with the following:

a. A.1 JORDAN® Trademark.

b. BS.

c. Nominal size.

d. Direction of flow.

| Size |

½" ,¾" ,1" ,1¼" ,1.1½" ,2" |

|---|

You must be logged in to post a review.

Reviews

There are no reviews yet.